Barcode labeling has become an essential part of modern business—whether you are in retail, logistics, warehousing, pharmaceuticals, automotive, or manufacturing. Every business needs accurate product identification, fast tracking, and reliable traceability. However, choosing the right barcode printing technology can affect productivity, cost, and label durability.

The two most widely used barcode printing methods are:

- Ribbon Printing (Thermal Transfer)

- Non-Ribbon Printing (Direct Thermal)

Both technologies are powerful and efficient, but each serves a different purpose. Understanding their differences will help you select the right barcode printer for your business.

http://thermaltransferribbons.tscprinters.co.in

What is Ribbon Printing? (Thermal Transfer)

Ribbon printing uses thermal transfer technology. A ribbon—coated with ink—passes between the printhead and the label surface. When heated, the ink melts and permanently bonds to the label material.

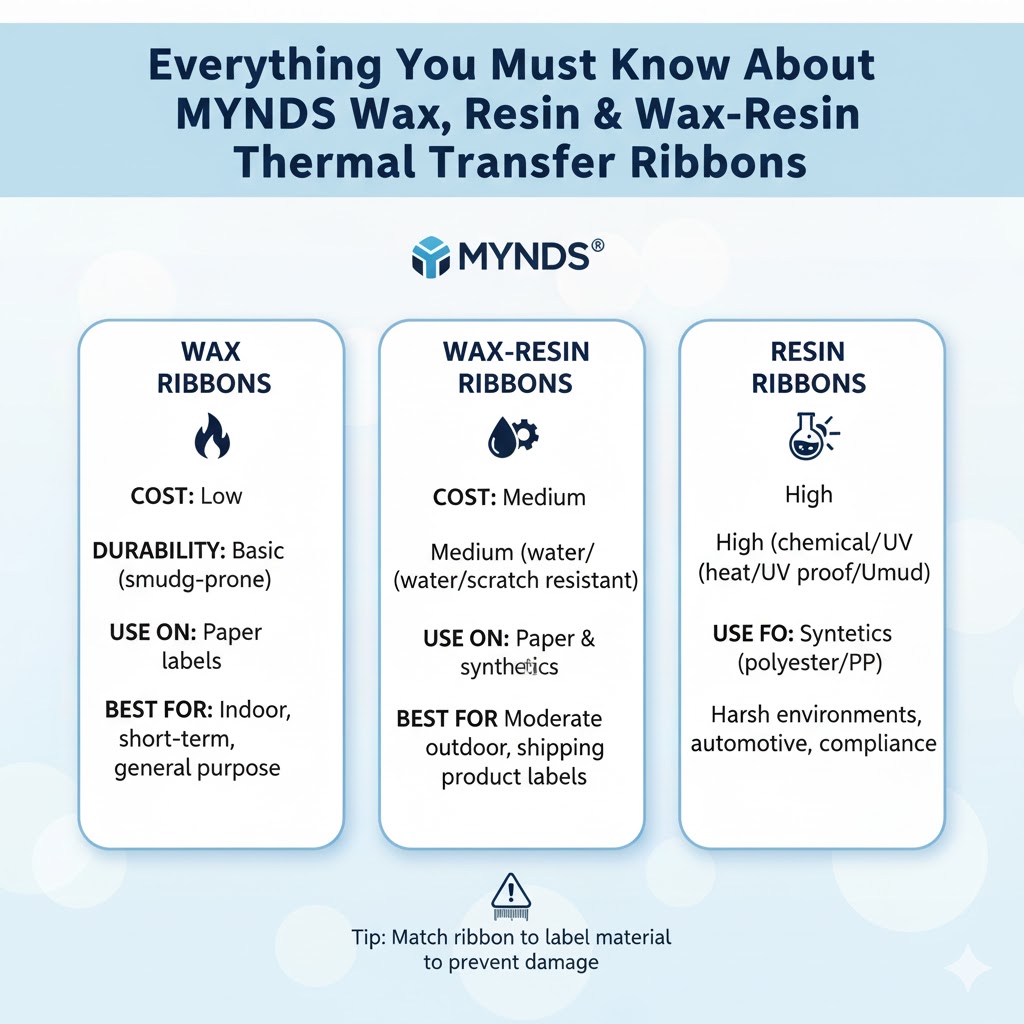

Thermal transfer printing supports various ribbon types such as:

- Wax Ribbon

- Wax-Resin Ribbon

- Full Resin Ribbon

- Wash-Care Ribbon

Because the ink becomes part of the material, the print offers:

✔ Superior durability

✔ High resistance to water, abrasion, heat, and chemicals

✔ Excellent barcode scan readability for years

Best applications for thermal transfer printers:

- Product labels for branding and barcodes

- Manufacturing and industrial components

- Asset tracking and inventory labels

- Pharmaceutical labeling

- Garment and wash-care tags

- Outdoor and harsh-environment labeling

In industries where labels must remain readable throughout the product lifecycle, ribbon printing is the most reliable method.

What is Non-Ribbon Printing? (Direct Thermal)

Non-ribbon printers use direct thermal technology. They print by heating specially coated thermal paper—without using any ribbon or ink. The print appears instantly when the paper darkens due to heat.

This method provides fast, cost-effective barcode printing, but the prints are not permanent.

Direct thermal labels eventually fade when exposed to:

- Sunlight

- Temperature fluctuations

- Moisture

- Friction

Best applications for direct thermal printers:

- Courier and shipping labels

- E-commerce packaging

- Supermarket billing labels

- Price stickers

- Retail POS receipts

If label lifespan is only 30 to 90 days, direct thermal printing offers excellent efficiency and affordability.

Major Comparison — Ribbon vs Non-Ribbon Barcode Printing

| Feature | Ribbon Printer (Thermal Transfer) | Non-Ribbon Printer (Direct Thermal) |

| Ribbon Requirement | Yes | No |

| Print Life | Long-term, permanent | Short-term (30–90 days) |

| Material Compatibility | All materials | Thermal paper only |

| Durability | Waterproof, scratch-proof, chemical resistant | Not durable |

| Cost of Printing | Medium | Low |

| Ideal Use | Industrial & manufacturing labels, wash-care, product IDs | Shipping & courier labels, receipts |

Which Barcode Printer Should Your Business Choose?

| Business Need | Recommendation |

| Long-lasting / industrial barcodes | Thermal Transfer (Ribbon Printing) |

| Short-term / high-volume labels | Direct Thermal (Non-Ribbon Printing) |

| Outdoor product exposure | Thermal Transfer |

| Low-cost fastest printing | Direct Thermal |

| Garment, wash-care, chemical labels | Thermal Transfer |

| Ecommerce packaging | Direct Thermal |

Why You Should Buy From a Manufacturer / Authorized Distributor

When purchasing a barcode printer, always choose a trusted manufacturer or authorized distributor because they provide:

- 100% genuine printers and spare parts

- Original barcode ribbons and labels

- Warranty support and AMC service

- Printer installation, configuration & training

- Better pricing for bulk orders

This ensures long-term reliability and smooth operations compared to unverified sellers.

Conclusion

Selecting the right barcode printing method depends entirely on the lifespan and purpose of the label. Ribbon printing (thermal transfer) delivers long-lasting, waterproof, and scratch-resistant results, making it the best choice for product identification, industrial tracking, wash-care garments, and manufacturing environments where durability is crucial. On the other hand, non-ribbon printing (direct thermal) is ideal for fast, affordable, and short-term applications such as courier labels, shipping stickers, and receipts.

Businesses that match their printing technology to their labeling needs benefit from cost savings, better productivity, and error-free barcode scanning. Whether you choose thermal transfer or direct thermal, purchasing from a trusted manufacturer or authorized distributor ensures genuine products, premium consumables, and reliable support. A well-planned barcode printing strategy ultimately enhances workflow efficiency and strengthens business performance.

For expert guidance, best prices, and genuine printers / ribbons / labels:

Call: 9717122688

Email: gm@indianbarcode.com

MYNDS / Barcode Vault – India’s Most Trusted Barcode Solutions Provider